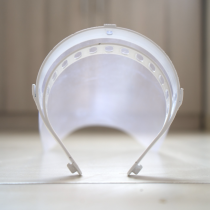

The Digital Manufacturing Laboratory (FabLab) of the University of Chile responded to the call of the Association of Manufacturers in the face of the Health Emergency (AFES) and designed a facial shield, 3D printable, compostable and at low cost.

The face shield is composed of a 3D printable belt – in polylactic acid (PLA), a polymer with PET-like properties, which is biodegradable under certain conditions at temperatures close to 60oC – and a letter-sized mica (such as bookstores). “It was clinically validated in conjunction with a UC-Christus Network physician. It is functional, complements the n95 masks, protects health personnel from the suspended virus and also meets the secondary objective of increasing the period of hygienic use of n95, which will be finished soon, so it is relevant to lengthen its use”, said Danisa Peric, director of the FabLab of the U. of Chile.

The design was inspired by a model by printer developers Prusa (Czech Republic), but – unlike the original – it does not require any drilling in the mica, which makes the process more hygienic and durable. “It’s geared towards being a device that’s massive, cheap and reusable,” Peric said.

“We joined AFES so that they could coordinate a network of national printers. Today they manage 300 professionals or offices who will make their printers available to process the orders that are being made,” she added.

After this first phase, which begins this Monday with the release of the design to those who want to manufacture it, the FabLab will focus on looking for a more massive manufacturing strategy. Danisa Peric explained that printing each belt takes 90 minutes, so with the 300 printers running, 300 belts could be obtained every hour and a half. But they want to multiply that amount by ten. “The second part is to be able to interpret this for mass plastic injection manufacturing. We are in talks with some manufacturers who have this ability to mass-manufacture it,” he said.

“AFES has this dual function, the first is to respond to the need for devices and equipment in the health emergency and, on the other hand, to support the national industry. Ethical prices consider some usefulness or support for the manufacturer who is also in crisis today. All this fabric of digital manufacturing services is about to go bankrupt today and we believe it can be supported,” Peric emphasized.

The design of the FabLab is under a Creative Commons license that allows its commercial use but under certain conditions. The sale price, for example, is fixed at an ethical price which in this case cannot be more than 7 thousand pesos without VAT. “This way of working, combining ideas that flow between a network of innovators, multidisciplinary talent, close contact with end users and effective transfer of knowledge assets to society, is the model we seek to drive strongly from the University, and that requires the participation of all sectors. We see that in the emergency we need to be a country strong in knowledge, in technology, in capacity to build solutions to the problems of society,” says James McPhee, vice dean of FCFM and director of the Engineering 2030 project, which with funding from CORFO and the University of Chile supports the work of FabLab.